- 09/10/2025

- Tips

Pecol Discs: Excellent Cuts, Perfect Finishes!

Discover how our Abrasive and Diamond Discs can elevate the excellence of your projects.

Selecting the right disc for a project is essential for several reasons. Firstly, it allows you to maximize efficiency and productivity, ensuring a high-quality finish while minimizing the risk of accidents. Additionally, choosing the correct disc can lead to long-term savings by avoiding frequent replacements and preserving the integrity of your tools. Finally, it ensures compliance with established standards and specifications, reducing the need for rework and guaranteeing consistent, long-lasting results. In summary, the proper choice of disc enhances the effectiveness, safety, and success of the project.

Abrasive Discs or Diamond Discs — which one to choose?

Discos Abrasivos PECOL

With a focus on high efficiency and cost-effectiveness, PECOL’s Thin Cut Abrasive Discs ensure outstanding professional performance when cutting a variety of materials.

- They provide faster cuts, reducing raw material waste.

- They minimize burr formation.

- They significantly reduce noise, debris, and smoke, ensuring a more comfortable and cleaner working environment.

Premium Long Life Thin Cut Stainless Steel Disc

The Premium Long Life Thin Cut Discs are specially designed for demanding cutting tasks on stainless steel, metal alloys, Hardox, and various ferrous and non-ferrous metals. They are ideal for cutting sheets, tubes, profiles, and components, whether hollow or solid.

- Free from iron, chlorine, and sulfur;

- Manufactured using advanced abrasive materials and resin technologies;

- Minimize heat generation during operation, enhancing cutting efficiency.

In addition to their true 1 mm thickness, the disc’s central flange ensures a more stable and precise cut.

Moreover, these discs are compatible with all machine models, while respecting the recommended peripheral speeds.

Premium Thin Cut Steel Disc

The Premium Thin Cut Steel Disc is the perfect disc for cutting steel and iron. Thanks to its robustness and cutting efficiency, it is ideal for use with an angle grinder in a wide range of tasks.

The disc’s helical surface design minimizes friction during cutting and significantly reduces heat generation. This ensures excellent performance when cutting various ferrous materials.

We recommend its use for tasks such as cutting piping tubes, metal profiles for plasterboard structures, metal sheets, and solid steel components.

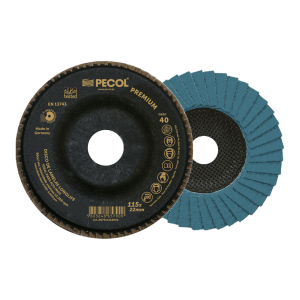

Flap Discs

Flap Discs are abrasive tools made up of overlapping flaps of abrasive material arranged radially. Designed to provide smooth and efficient finishes, they are ideal for material removal and polishing on uneven surfaces. The flap structure allows for cooler operation, minimizing damage and offering versatility for both grinding and finishing across different materials.

Premium Long Life Stainless Steel Flap Disc

The Premium Long Life Stainless Steel Flap Disc stands out in the grinding and finishing of steel and stainless steel, thanks to its composition of 100% pure zirconium and cooling agents. This innovative formulation provides superior performance compared to conventional discs. The backing plate, made from natural and eco-friendly fibers, wears evenly along with the flaps, maximizing abrasive use and extending the disc’s lifespan.

Premium Multi-Surface Flap Disc

The Premium Multi-Surface Flap Disc features a self-wearing natural fiber backing plate, ensuring full use of the abrasive until the end. With its hybrid ceramic abrasive and eco-friendly plate, this disc delivers superior performance, significantly reducing both operation time and costs by more than 50%.

Premium Tornado Flap Disc

The Premium Tornado Flap Disc is ideal for heavy-duty steel grinding, ensuring a high removal rate of up to 1 kg of material in 20 minutes. With zirconium grain and cooling agents, it provides superior wear resistance. The design featuring a self-wearing natural fiber backing plate maximizes abrasive use, optimizing the performance and efficiency of the grinding disc.

PECOL Diamond Discs

Diamond discs are high-precision cutting tools ideal for extremely hard materials such as concrete, ceramic, and stainless steel. Thanks to their diamond-segment composition, they offer excellent wear resistance and maintain sharpness even under harsh conditions. These discs ensure clean cuts, reduce burrs, and are essential for applications requiring high-quality finishes, standing out for their durability, precision, and versatility across various industrial and construction sectors.

The Furacão Silent Laser Diamond Disc represents an advanced innovation in diamond disc technology, renowned for its professional performance and quality. Featuring a double steel core that reduces vibration and noise, this disc has a 12 mm segment height with uniformly positioned, titanium-coated diamonds. This design ensures precise cuts and extended segment life. The special hole pattern allows for efficient cooling, making it suitable for use in demanding conditions. Ideal for cutting concrete, reinforced concrete, and granite, the laser welding enhances safety by ensuring the segment’s structural integrity on the disc.

In summary, abrasive and diamond discs are essential tools for a wide range of industrial and construction applications. With advancements in technology and design, they offer features such as self-wear capability, efficiency, and sustainability. Choosing the right disc is crucial to ensure high-quality results, safety, and long-term cost savings.

Don’t fall behind! Choose the ideal disc for your project now and take efficiency and quality to the next level.